This is an Organizational design

We have this culture at MediaLab Amsterdam wherein each team prepares Monday-lunch for other teams. It is a cycle and this time just before the sprint review we had our turn to prepare the Monday-lunch for everyone.

We were going to prepare Indonesian cuisine and Andrew was the head chef (he was just following his mother’s instructions).

Everyone thoroughly enjoyed the lunch and we couldn’t thank Andrew’s mother enough for her generous support and help.

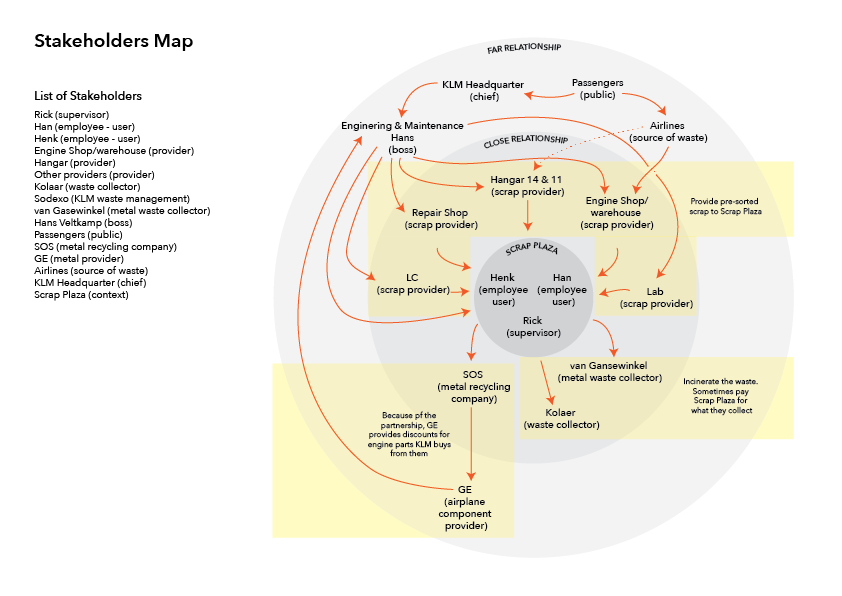

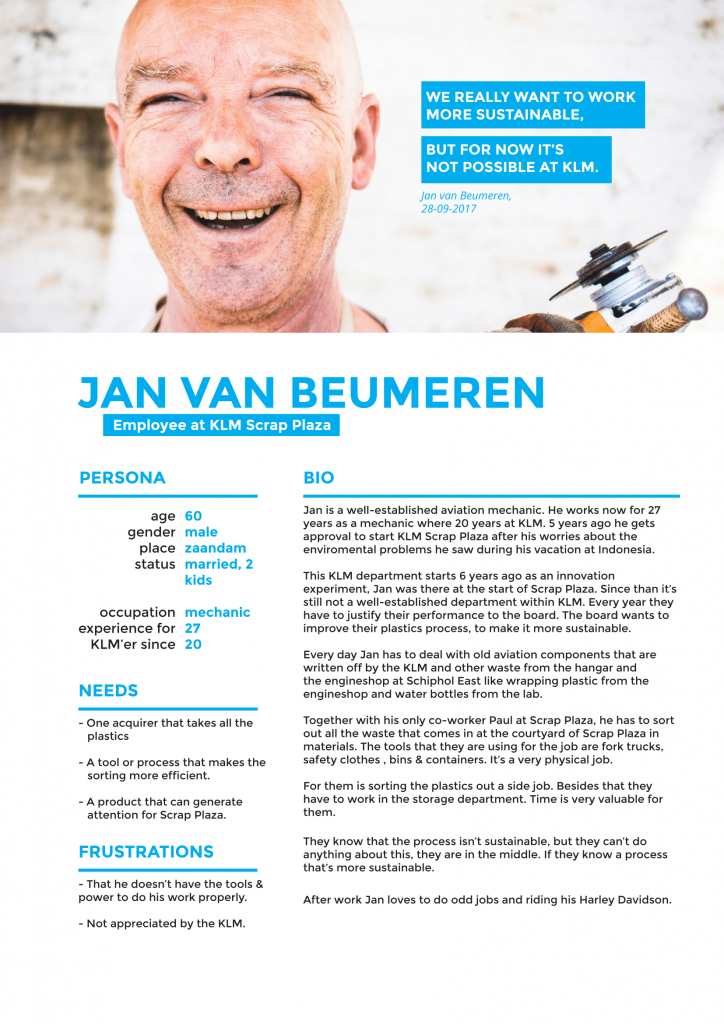

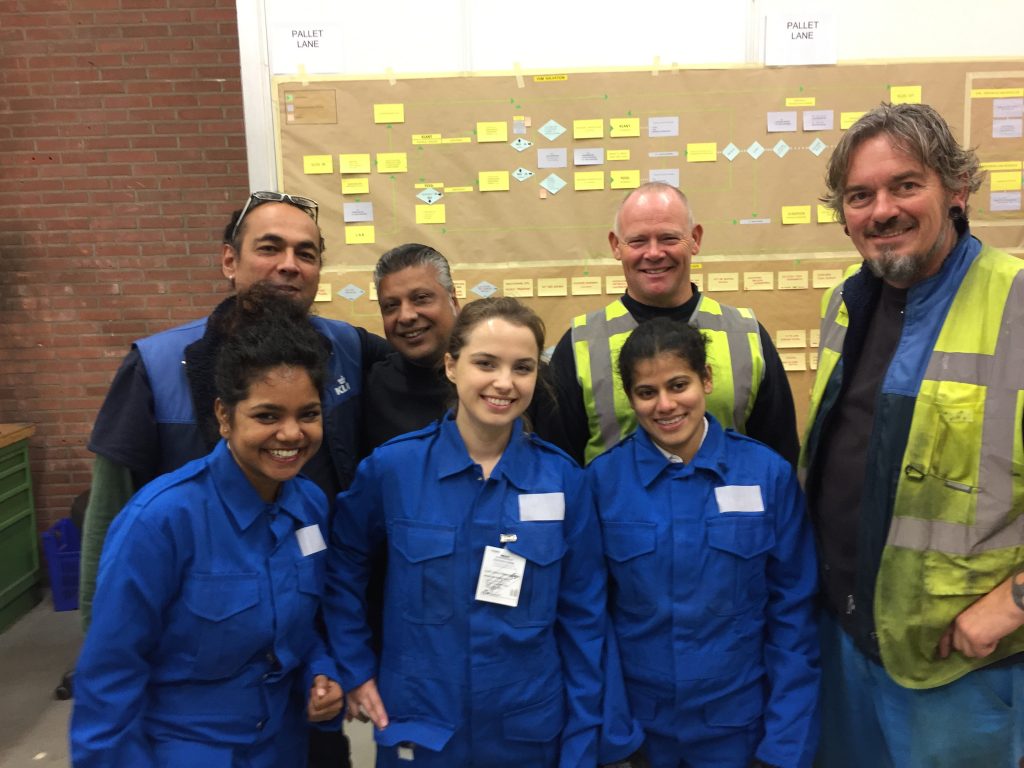

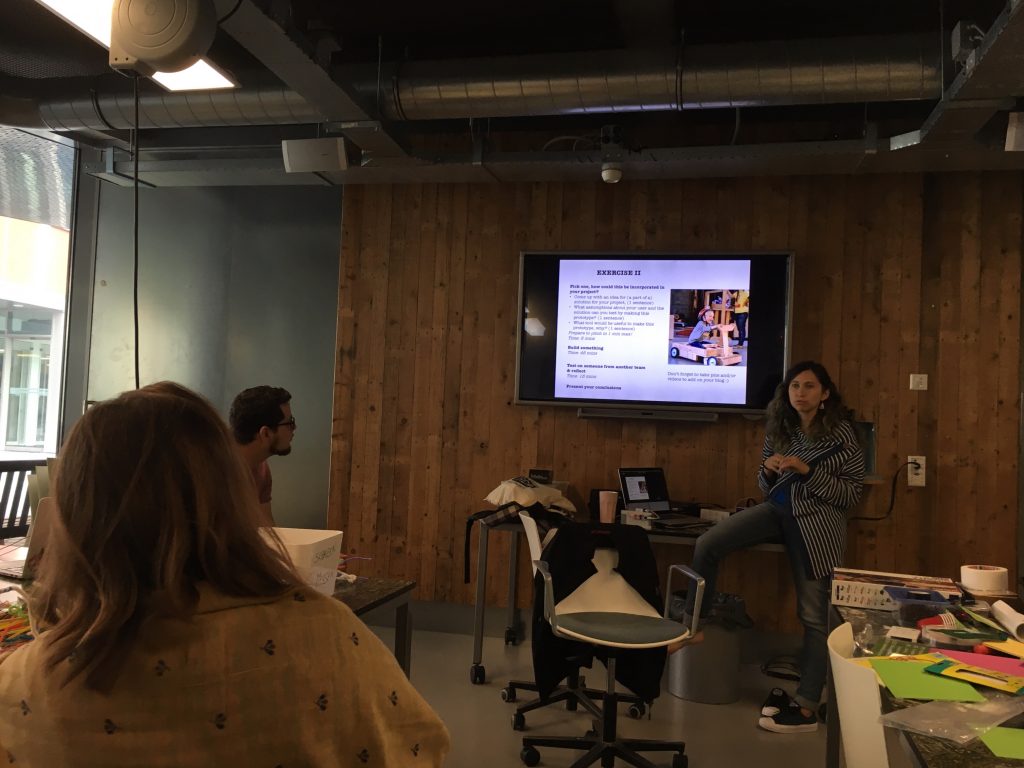

Apart from that, now was the time to look at the whole picture and showcase each problem that we were tackling with the solution that were offering. Specially, after focusing on defining the destiny for the sorted plastic at KLM Scrap Plaza in the previous sprint we realised that it was necessary to show the bigger picture to our clients. The wholesome view as we call it.

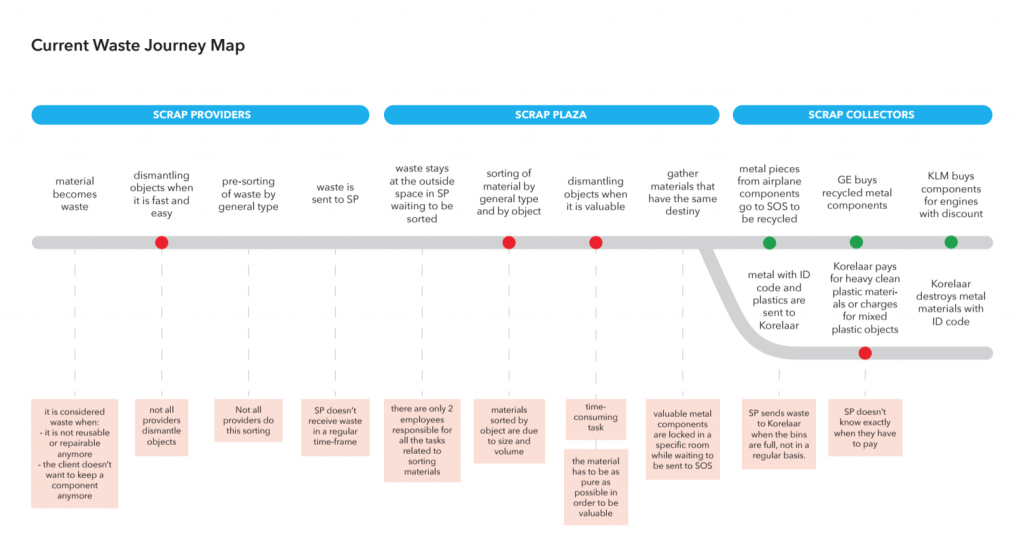

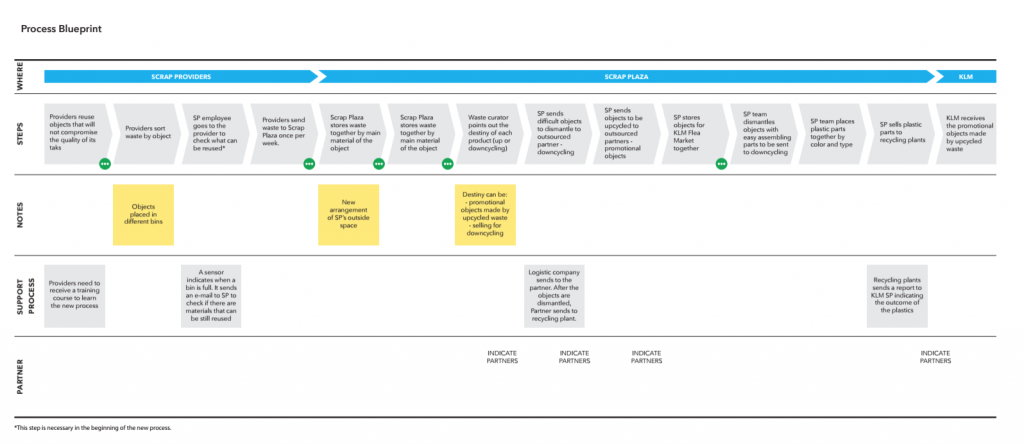

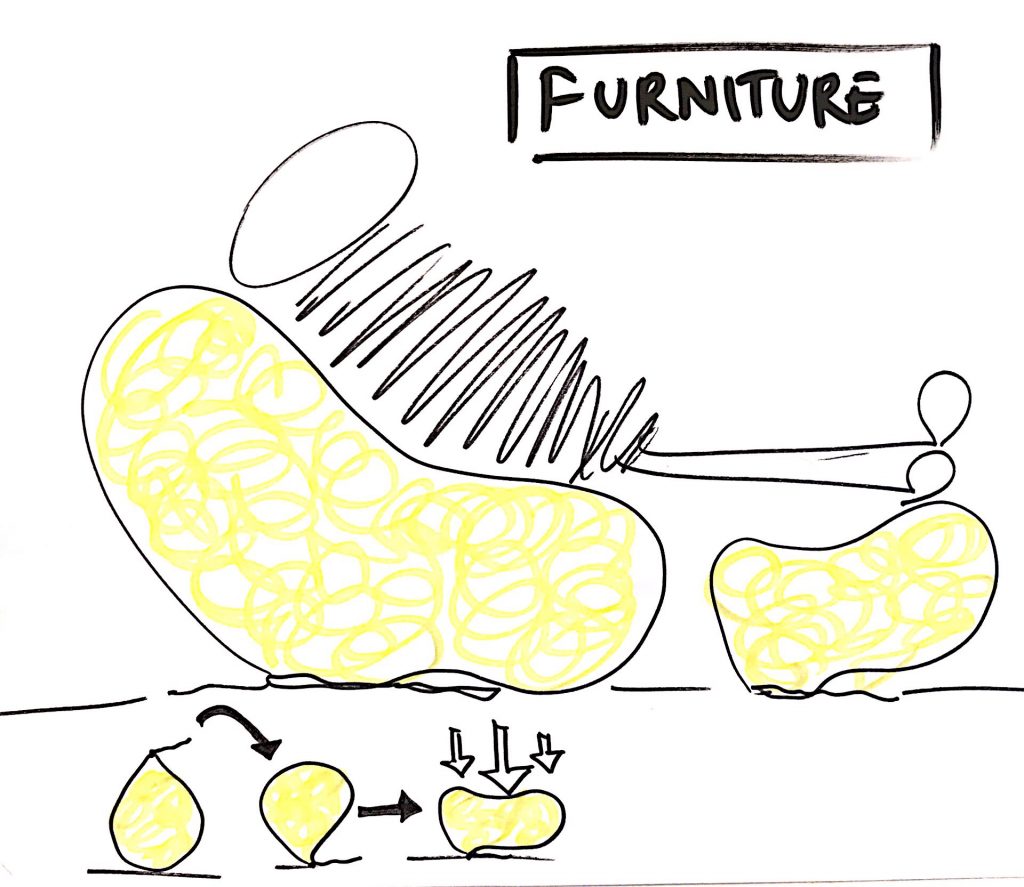

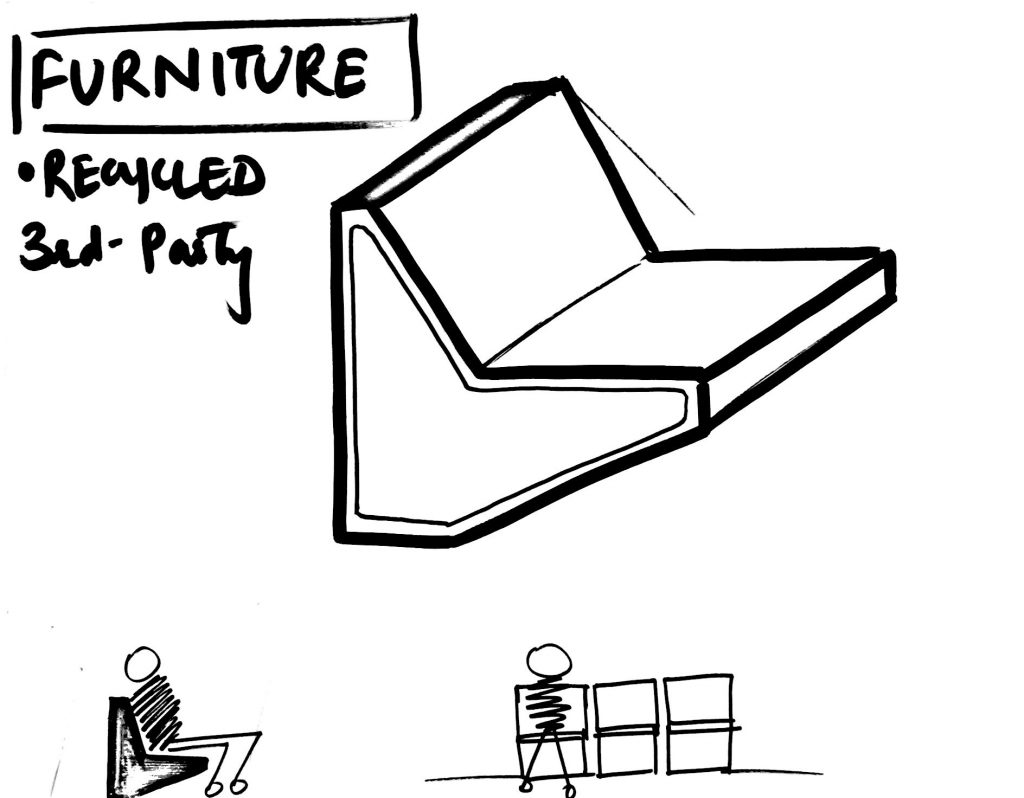

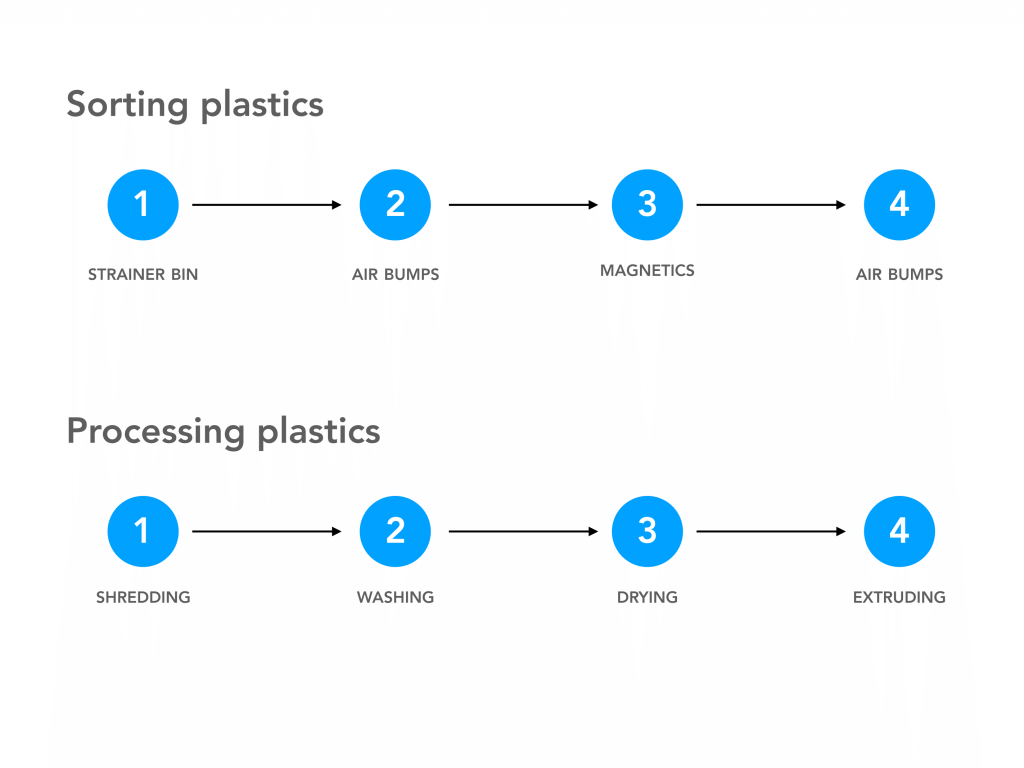

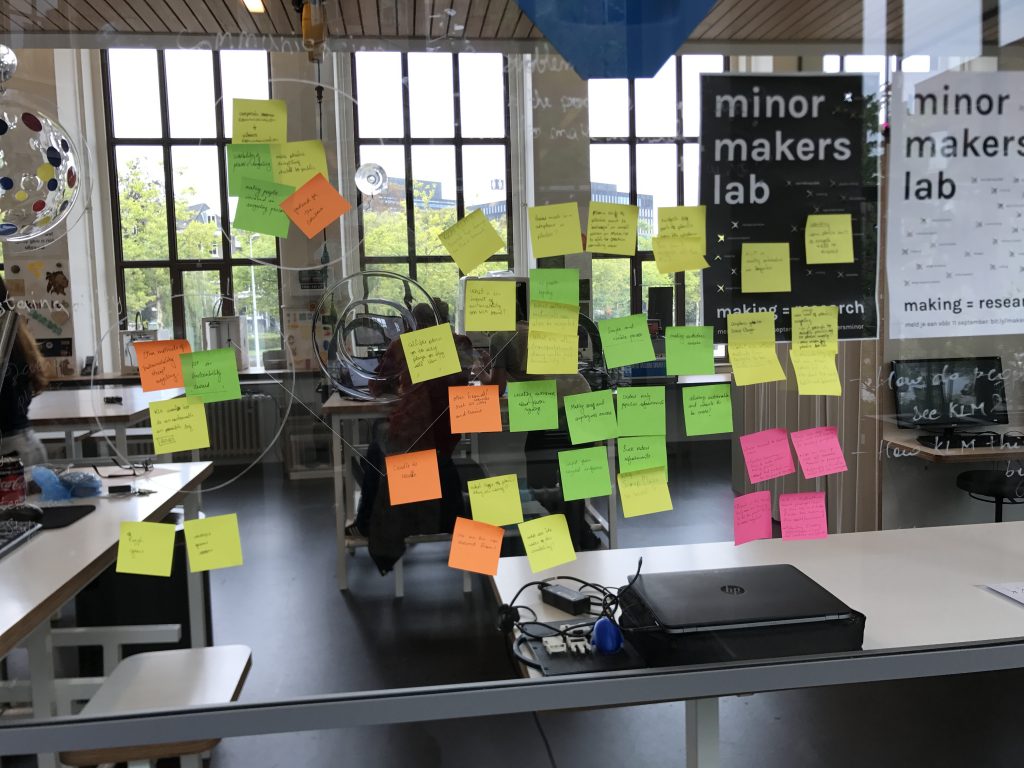

We refined the waste journey map and service blueprint. In short we improvised their existing process from handling of plastic waste to sending it to potential recycling (down-cycling/up-cycling) partners. During this refinement we also realised that what we are actually designing is an organizational blueprint. Hence, we decided to call it as an Organizational Design project from here on.

During our journey on this project we targeted 3 main issues and those were:

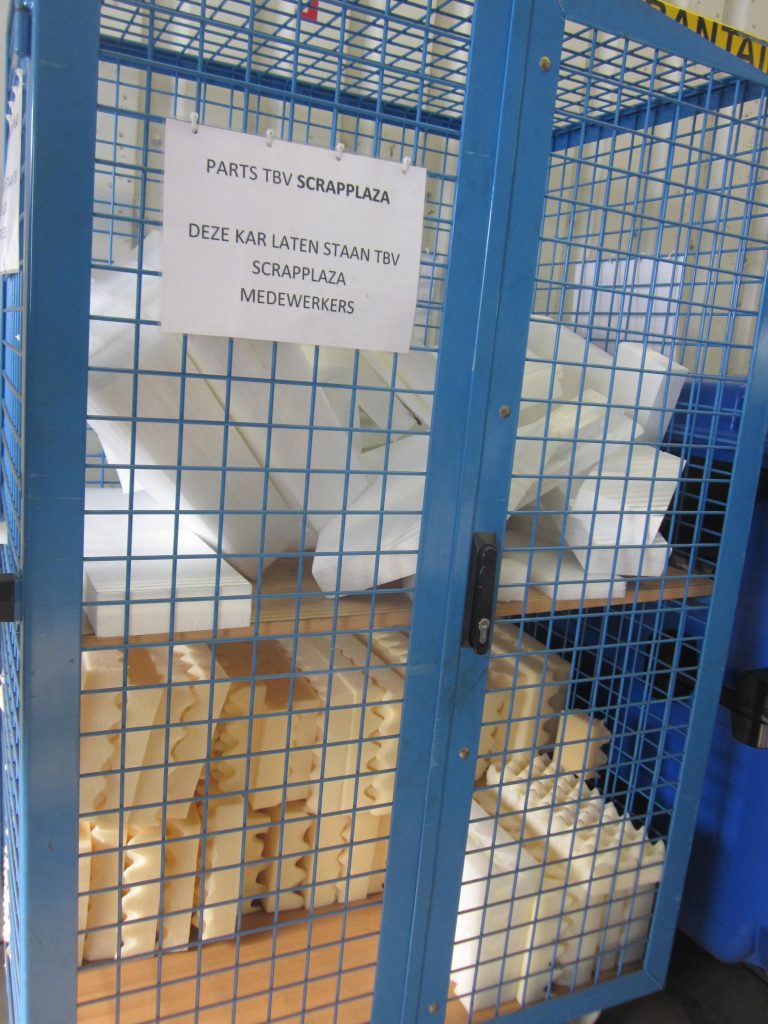

1. KLM Scrap Plaza and its providers do not have a method to sort the plastic waste.

2. KLM Scrap Plaza and its providers do not monitor the plastic waste that comes and goes out of their units.

3. Finding partners that provide transparency and sustainable handling of plastic waste.

As a solution to these problems we offered:

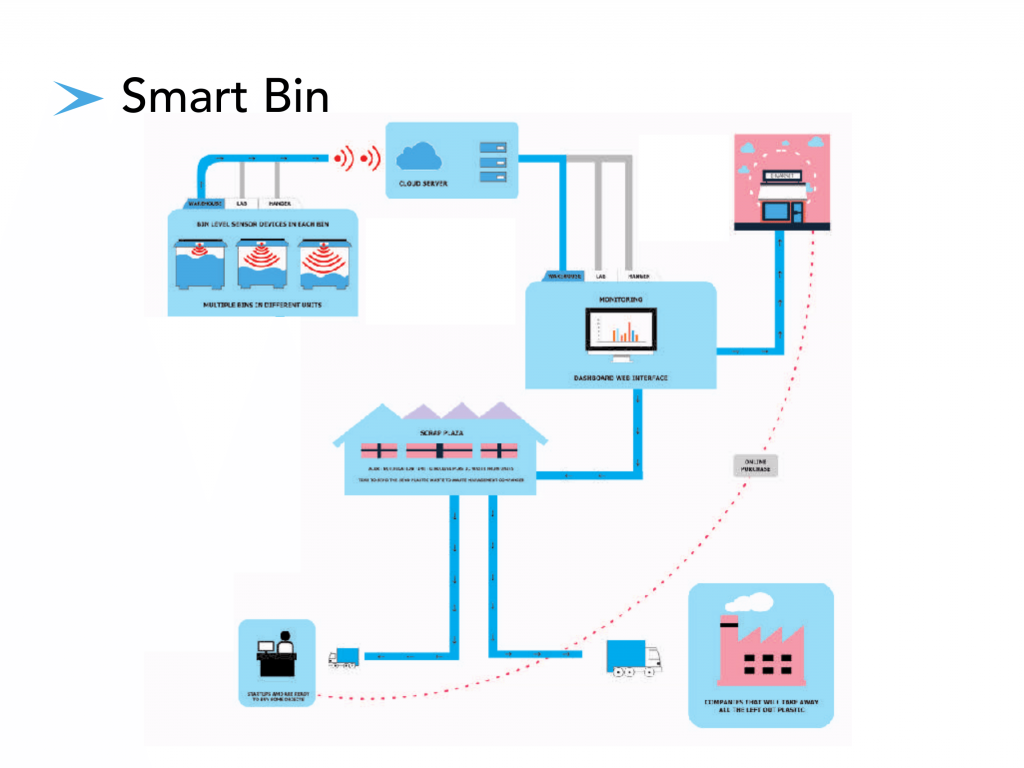

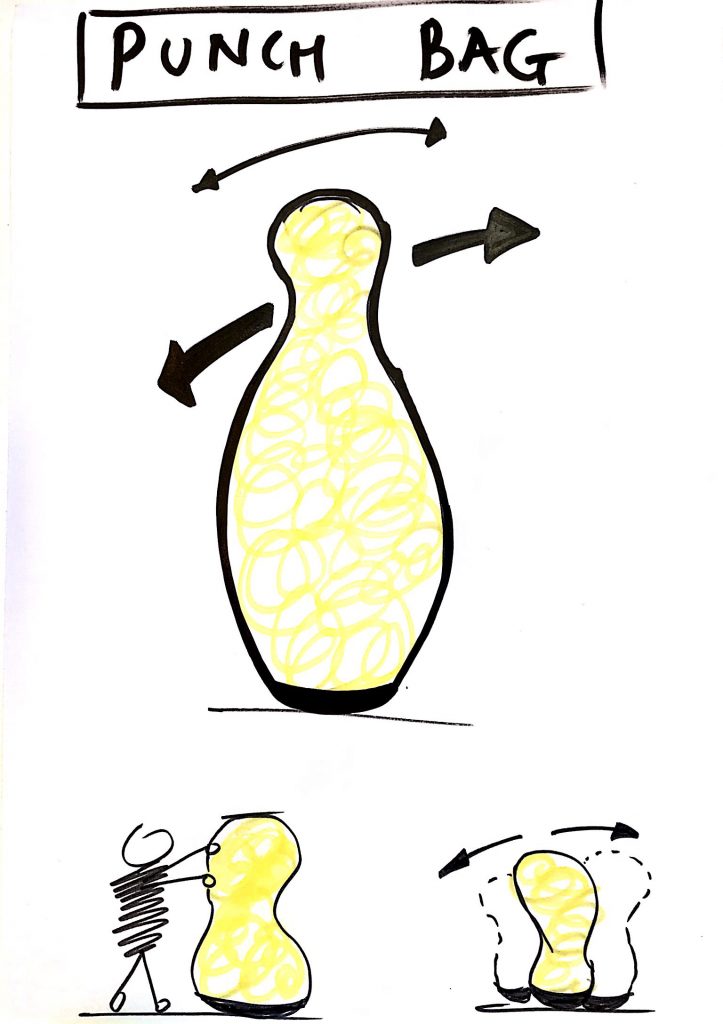

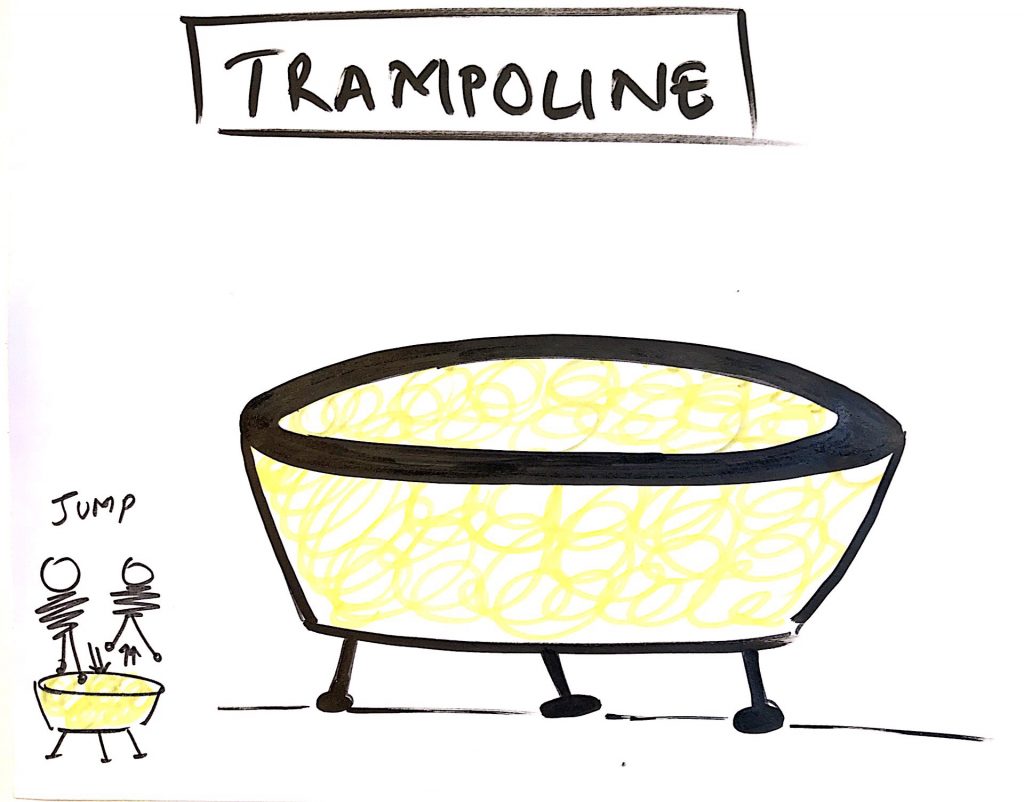

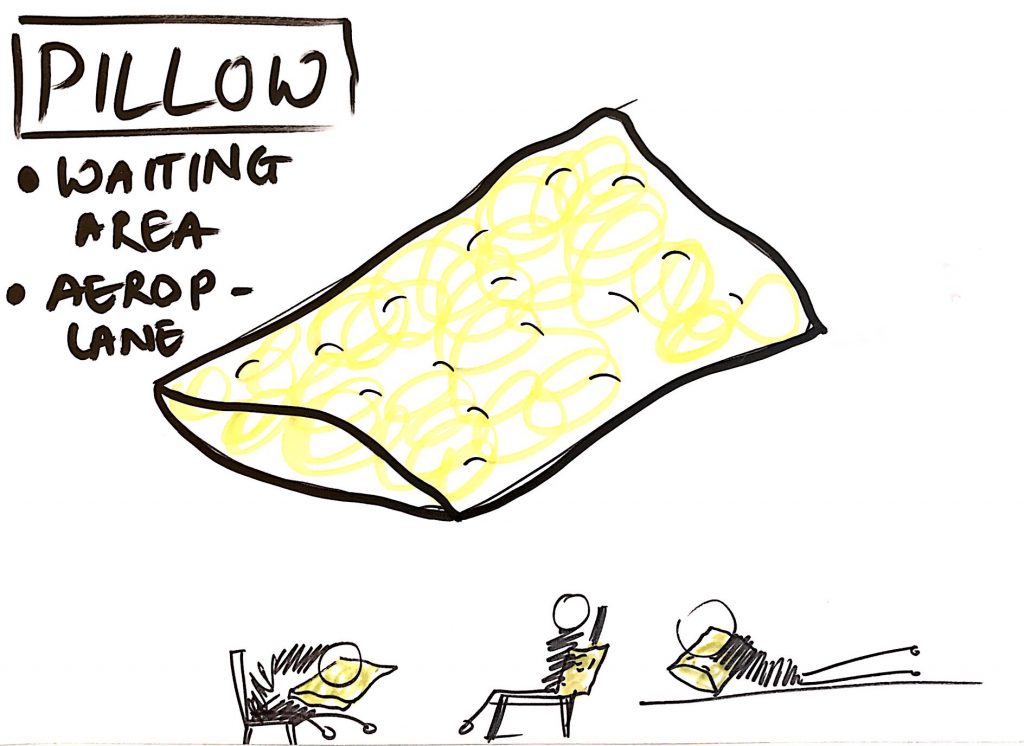

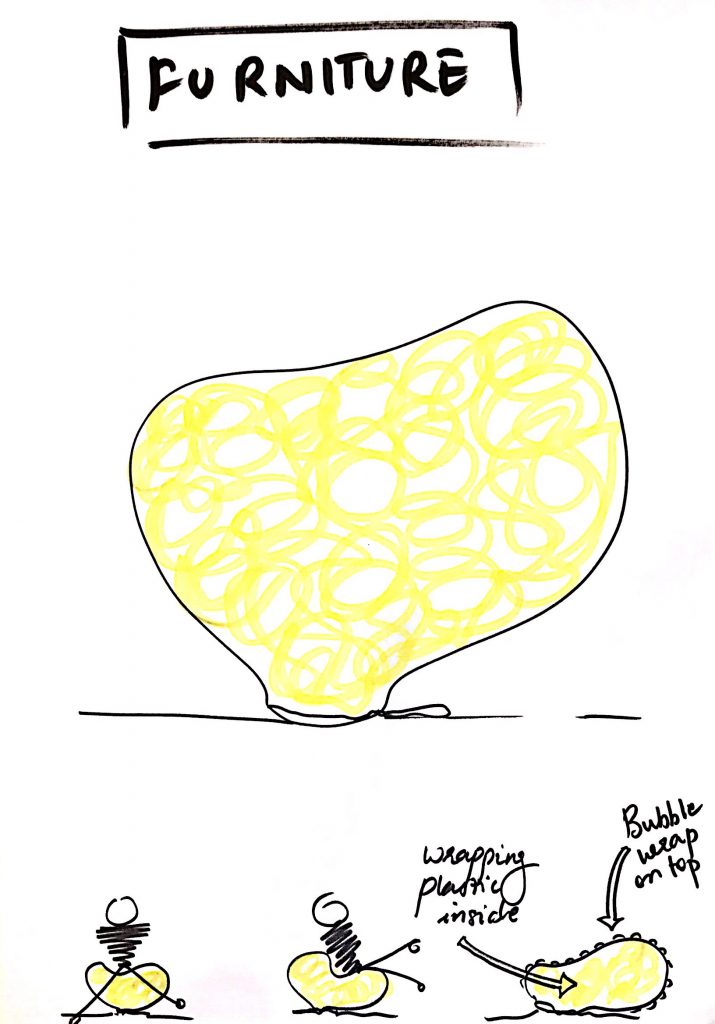

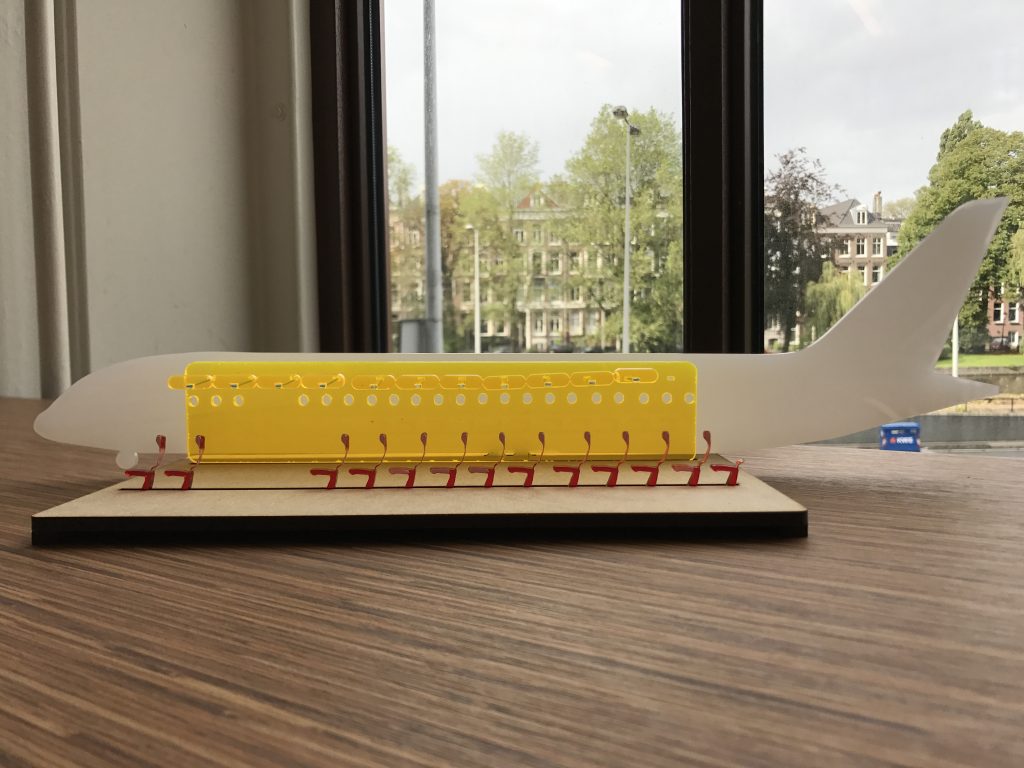

1. Smart bins

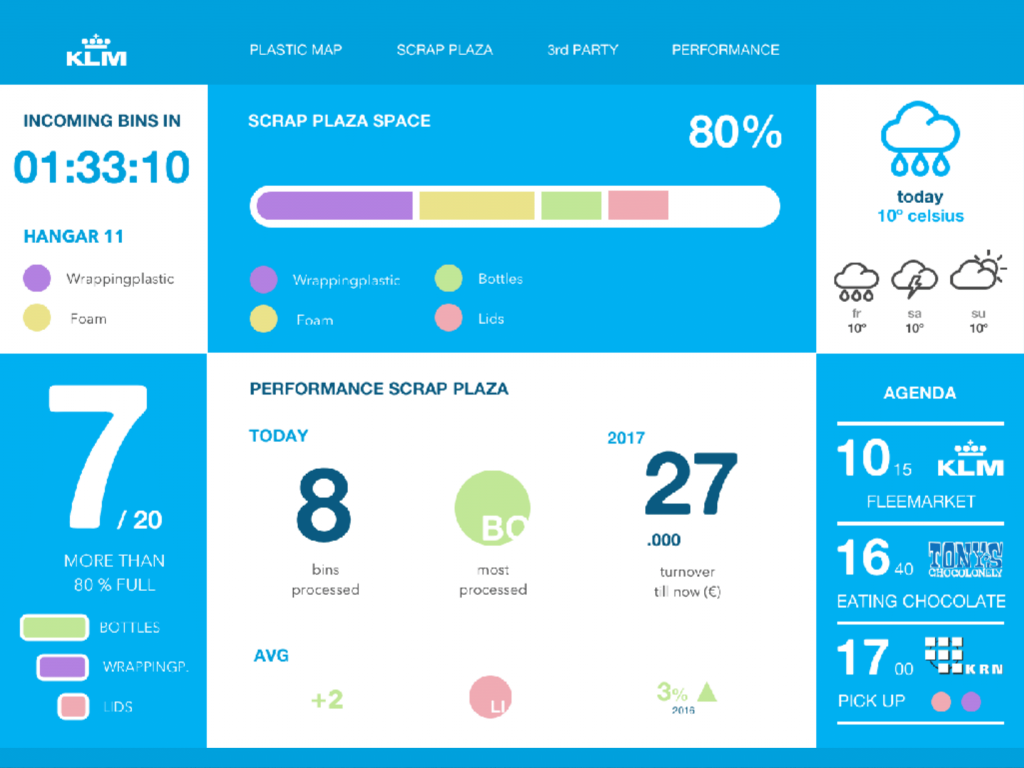

2. Analysed their current plastic flow in and out of the KLM Scrap Plaza and defined elements and functions for the monitoring tool. During the analysis it was found that the data was incomplete. Hence, for the year 2016, the percentage of plastic waste is inaccurate manifesting the fact that data monitoring was essential.

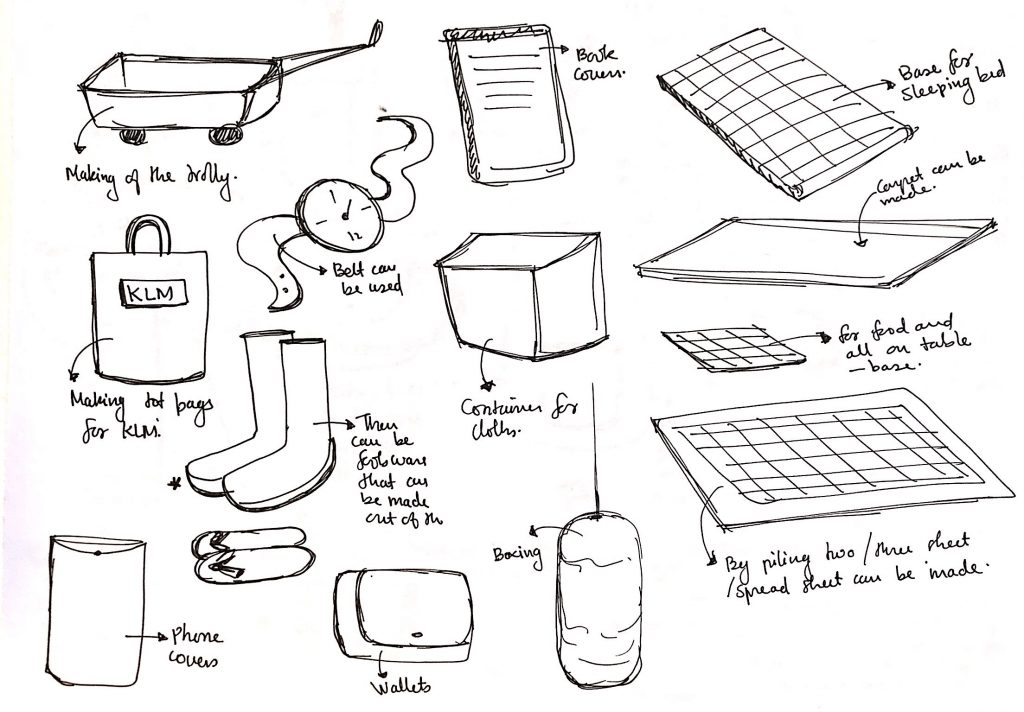

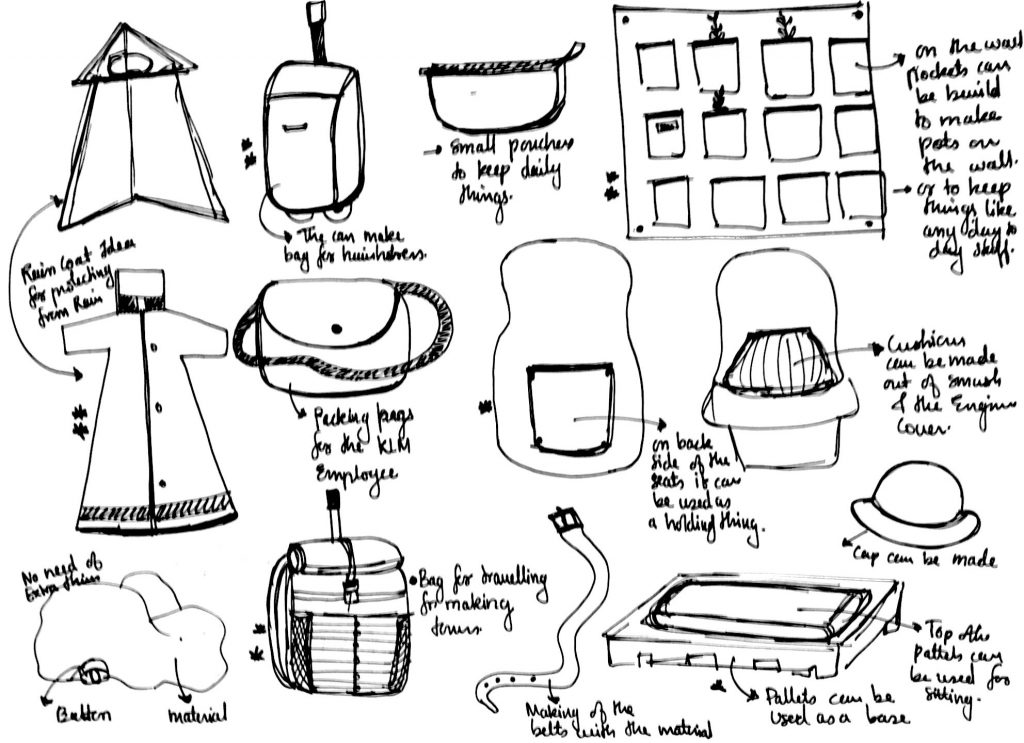

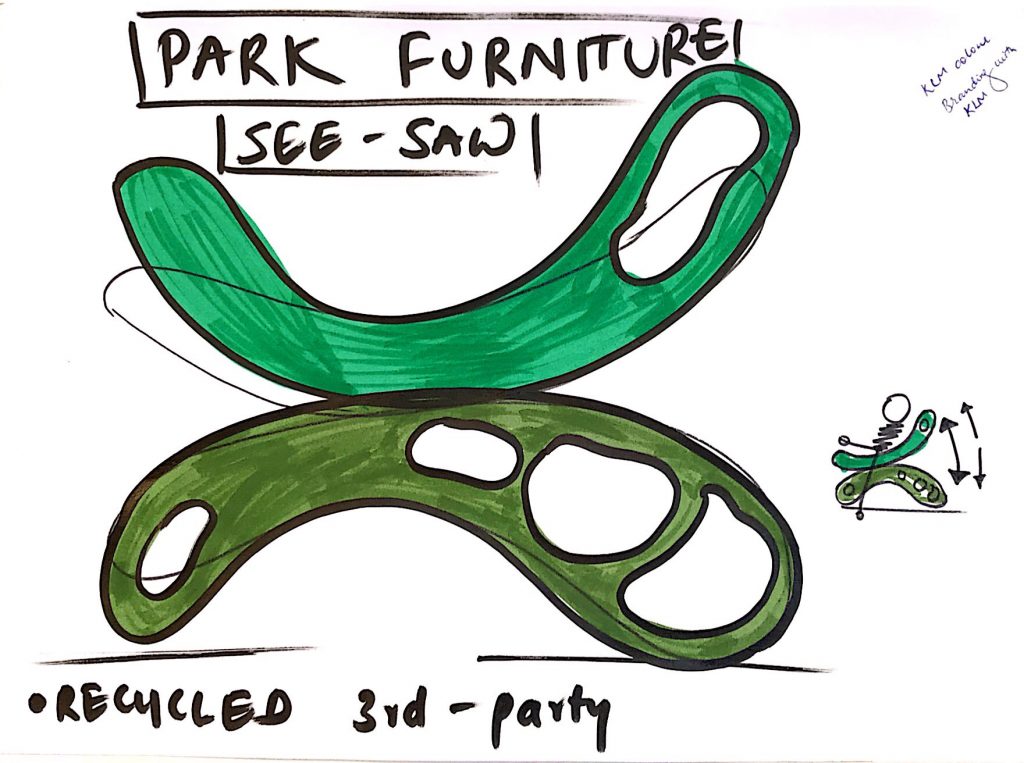

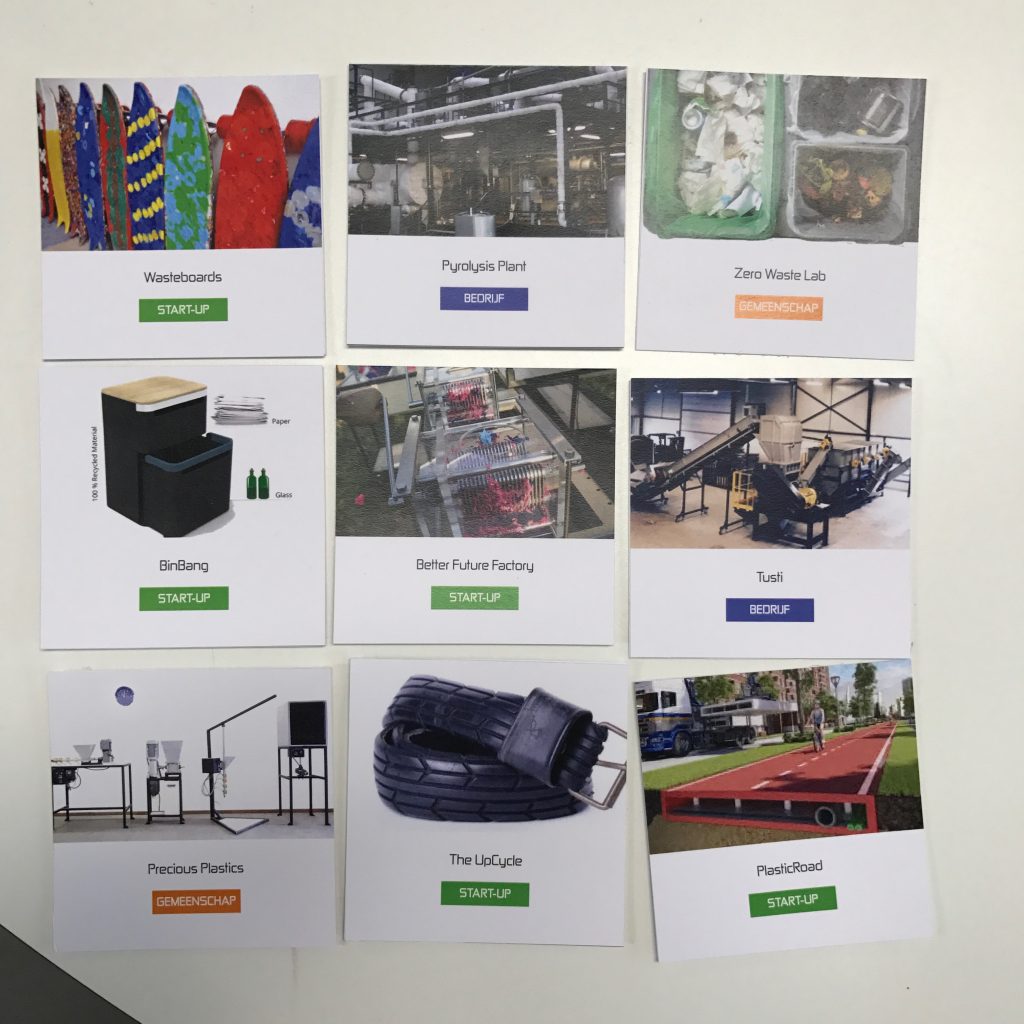

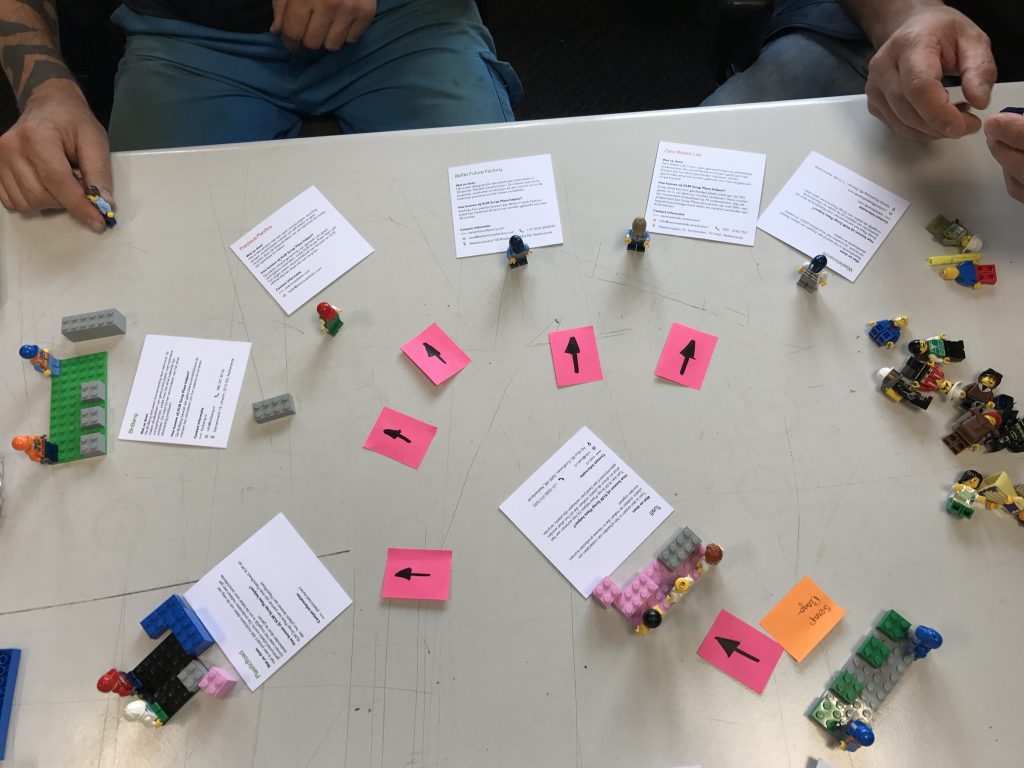

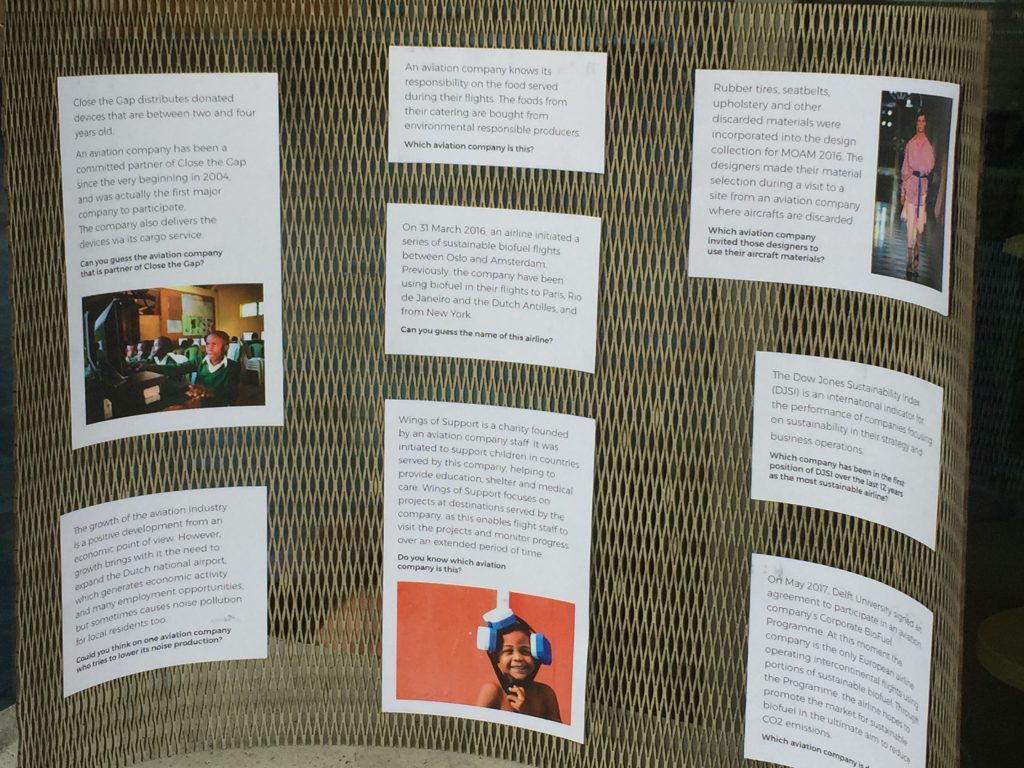

3. Providing information of potential partners for down-cycling, up-cycling and introducing a platform such as E-shop to sell used or waste plastic as a raw material to individuals and industries.

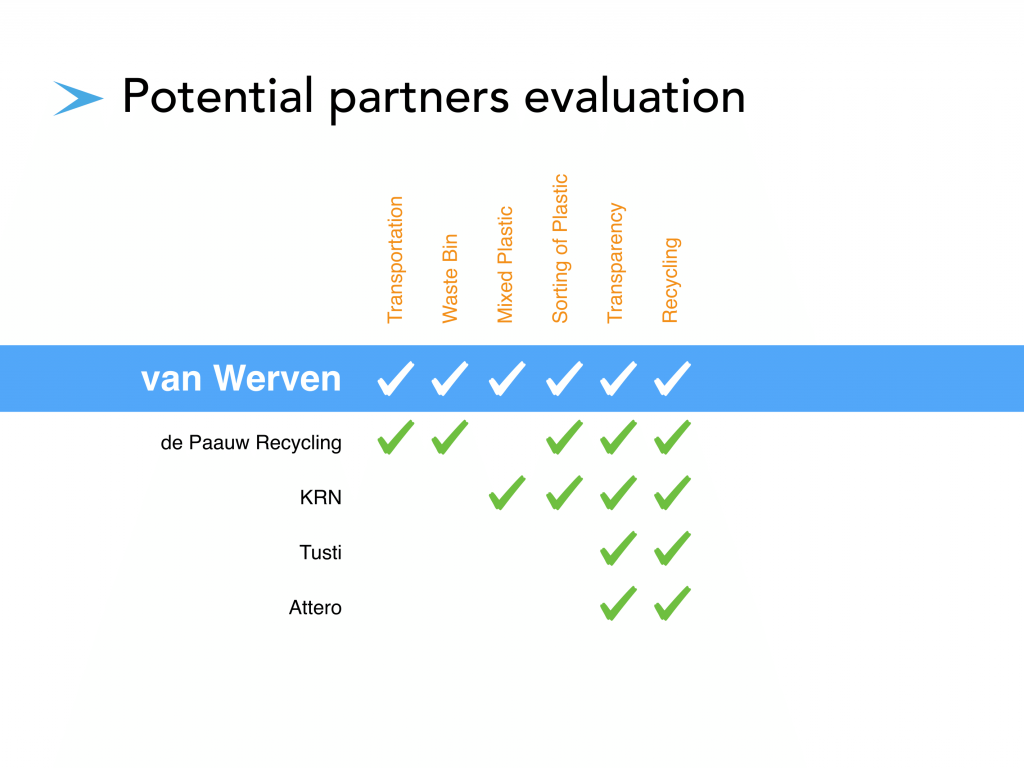

In this sprint we had many tasks to accomplish. Sprint goal was clear and sub-goals too. Camila and I were responsible for contacting potential partners. This list of potential partners will contain as much information as possible. Information such as the types of plastic waste their company accepts, the procedure it follows to downcycle/up-cycle the plastic waste, the rates they offer to purchase the plastic waste and other facilities they provide such as transportation etc. It was not difficult to gain the information but it was time consuming and required persuasion.

Many companies were reluctant to give exact figures. Some provided us with the cost of purchase while others mentioned that it is very subjective depending on the material and quantity. It was overall a nice learning experience for Camila and me. We had the opportunity to use our business administration skills to gain more insights and develop a strategy for organizational design.

Also, Simone Martens was our translation expert for this sprint and her networking experience and insights were extraordinarily helpful to our project. She got us connected to few other companies and organizations recycling or up-cycling plastic waste. We couldn’t have expanded our knowledge without her contribution.

Sarita was focusing on Smart bins. Her motto was to learn and replicate the functionality of the sensors. Along with one of the coaches, she was iterating various codes to get the sensor feedback.

Andrew on the other hand was responsible for the monitoring tool with complete functionality.

He studied the user, their needs and understood the environment of the user too for the site map. This site map helped us understand the factors of the monitoring tool and its use in the organizational design.

Together we finalised the entire process with the steps and key points. We also defined the connection between various factors and functions such as the communication between the monitoring tool and smart bins.