We have been keenly following ‘Precious Plastics’ since the beginning of our project with KLM Scrap Plaza. Hence, we decided to set up a meeting with one of their chapters ‘Precious Plastics Den Haag’ at the Museum Boijmans Van Beuningen, Rotterdam. Suzanne Koops manages the ‘Den Haag’ chapter for ‘Precious Plastic’. She was a very kind and generous host for accepting our invitation to see the project she has been working on since past few months. It was our first field research trip.

Previously we had only been studying, observing and researching at our client’s site and Medialab. We were excited to see the recycling machines and the range of products that can be made using these machines on our field trip.

The best part of field research trip is that we get to learn having fun. After the meeting with ‘Precious Plastics Den Haag’, we visited the Museum Boijmans which was exhibiting a special kind of exhibition at the time called as ‘Change the System’.

Personally, I am thrilled to see the fine entanglement of my skills while I am working for #teamklm2017 and #klmcares. I see how beautifully I get to use my analytical skills of being a Mechanical Engineer and my technical knowledge and why it is necessary to extract and use all this data for user research, user need and user experience. As each day passes by, I am having a deeper understanding as to why these fields which are so diverse in their own existence must come together to solve the user problems to satisfy the user better, day by day. This doesn’t just go for me but for my entire team. We all must take our background experiences in hand and walk ahead to tackle each issue that comes our way.

Our second filed research trip was at Dutch Design Week at Eindhoven.

This is an annual event to inspire and promote various trends in Design industry and to blend it with business.

We got to see many creative ideas. Another fun part was that we did not just go alone but along with VR team.

It is wonderful to see at one thing from a different perspective. Visiting DDW with VR team was one such experience for us. We were so focused on how to recycle the plastic that we had forgotten the fun of trial and error. The diversity factor that is offered at Medialab is something to be taken advantage of. Taking a break sometimes help and even though we were there to take inspiration from various industries which dealt with plastic recycling, we did involve ourselves into a wholesome experience of DDW.

Finally, we were able to gather some information for potential partners and some ideas for plastic waste.

We started our 2nd sprint from 2nd October.

All the sprints begin with sprint planning which includes goals and sub-goals and all the sprints end with retrospection. We decided to visit KLM Scrap Plaza on 5th October with the intention of figuring out their top 5 voluminous plastic objects (white bottles, foams, pallets, engine covers and wrapping plastic). The conclusion from 1st Sprint led us in this direction. KLM Scrap Plaza receives many random plastic objects and to sort all at once was going to be a tedious task. To narrow down our focus and research we wanted to select only those objects which are either large in volume or are often dumped at KLM Scrap Plaza.

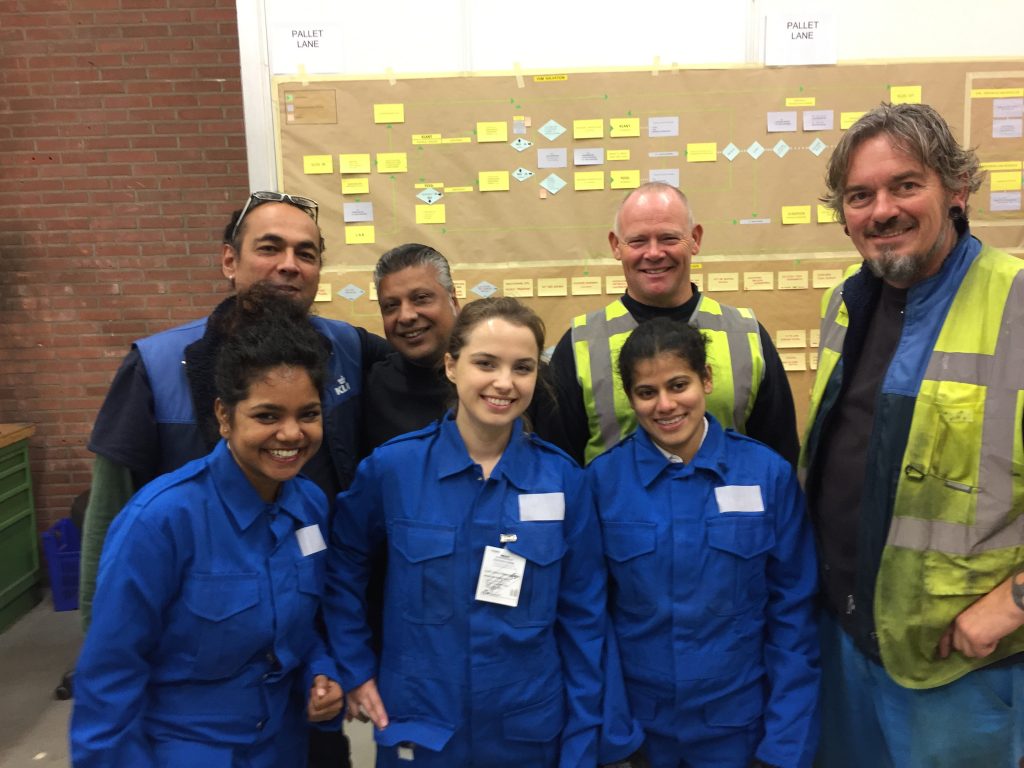

After the 1st Sprint research and dynamics it was clear that whether KLM Scrap Plaza was interested in upcycling and/or downcycling of their plastic waste, sorting of the plastic waste into different types of plastics and colours was inevitable. All the study we carried out indicated that it is necessary for the plastic to be sorted according to its type for recycling process. It is even better if it is further sorted according to its colour. So, we gave an emphasis on sorting of the plastic as a prototype for the 2nd Sprint. It became necessary for us to train and educate the employees at KLM Scrap Plaza to sort the plastic waste according to its appearance if not by type.

To make them understand this procedure of sorting we decided to make an informative video. Also, to incorporate this sorting method into their daily working life, we insisted on prototyping a working sorting system at their site. This would mean they will be using this sorting system on daily basis and would provide us with the necessary feedback.